For 13 years we were fortunate enough to establish and run our own flock of Southdown sheep. It was a unique opportunity to get to know this wonderful, docile and friendly breed of sheep but also to make long lasting and cordial connections with the Southdown sheep farming community throughout the UK.

But as all farmers eventually have to concede, we get too old to cope with the enormously strenuous, physically demanding and dangerous task of farming. Retirement from farming thus called. This occurred just at a time when sales of our beautiful Southdown duvets increased to the point where we needed to acquire a lot more wool than we could produce annually ourselves.

So we now buy our wool from recognised Southdown breeders, all of whom we deal with directly. While this allows us to confirm full traceability of the wool and the appropriate animal welfare practices, it also ensures that our farming partners get a premium price in recognition for supplying their precious wool. (Read here for more about the Southdown Duvets’ Wool Buying Scheme)

Shearing takes place across the country, usually in early summer and shortly after lambing. The shearing is timed to protect the ewes from the worst of the summer flies.

The wool is then sent to the British Wool Marketing Board who compact it in Bradford ready for shipping to Italy.

The Breeders Flock Book – the official cohort of Southdown wool producers

Shearing frees the ewes from their winter fleeces

Sheared wool leaving the farm

British Wool assists with logistics

Once at our factory situated in the foothills of the Italian Alps, the wool is sorted by hand and repacked ready for scouring.

The village of Miagliano, nestled in the foothills of the Italian Alps

And the wool arrives in Miagliano

The wool is hand sorted in our factory, in preparation for scouring

Scouring is a messy business but the wool is washed from the crystal clear waters of the Cervo River, using only a bio-degradable detergent.

The end result is perfectly clean duvet filling without a hint of any sheepy smells.

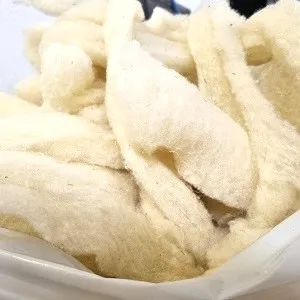

Once washed, the wool is then carded before being delivered to the manufacturers, a family business who have been making duvets for generations.

There in the factory, the outer percale cotton cover and wool filling are united on an automated machining bed and precision quilted to secure the wool in the duvet to prevent any slippage or bunching.

The crystal clean Cervo river

Carded wool

A correctly quilted duvet

Quality control at every stage

Each stage of the process is carefully checked and once off the machining bed, the duvets are inspected before being sent to the sewing team for hand finishing.

They are then finally packed and sent back to us in the UK ready for sale.

In keeping with our commitment to the environment, our mailing bags are fully recyclable.

Ready for finishing

Hand finished

Ready for delivery to you

Marsh House

119 Marsh Lane

Yeovil

BA21 3BZ

United Kingdom